The push for low-carbon energy is making rare earth elements (REEs) more in demand. These elements are key for things like wind turbines, electric vehicles, and advanced electronics1. But mining them can harm the environment with toxic waste and pollution. Recycling REEs is a better way to get the materials we need for clean energy2.

Right now, only about 1% of rare earths get recycled from old products3. But by 2040, we’ll need seven times more of them3. This makes a circular economy approach crucial. Companies like Cyclic Materials are leading the way. They plan to open six rare earth recycling plants in North America by 2035. This could help make 6.3 million electric vehicle motors3.

Key Takeaways

- Rare earth elements are critical for clean energy technologies, but mining them can cause significant environmental damage.

- Currently, only around 1% of rare earths are recycled, but demand is expected to grow significantly in the coming decades.

- Companies are investing in rare earth recycling to create a more sustainable supply chain for clean energy technologies.

- Recycling can reduce reliance on China, which currently dominates rare earth production and refining.

- Innovative approaches like biomining and agromining offer more sustainable ways to extract and process rare earths.

What Are Rare Earth Elements?

Rare earth elements (REEs) are 17 chemical elements crucial for the global energy shift4. They are split into light and heavy types, like cerium and dysprosium4. These elements are vital for clean energy tech, from wind turbines to electric vehicles and energy-saving lights.

Rare Earth Elements Definition and Types

The group includes 15 lanthanides, scandium, and yttrium4. But, they’re not rare in the earth’s crust5. Cerium is the 26th most common element, and neodymium is more common than gold5. The problem is getting them out of the earth economically.

Importance of Rare Earths in Clean Energy Technologies

Rare earths are key for many clean energy techs6. Elements like neodymium and dysprosium are used in EV motors and wind turbines4. Yttrium and scandium are in hydrogen electrolyzers, and europium is in energy-saving lights4. They also help in traditional energy use, like car exhaust catalysts4.

Over the years, the demand has changed, focusing on neodymium and others6. This is because they’re vital for energy storage and conversion tech6. As we move towards cleaner energy, rare earth prices are likely to go up6.

“Rare earth elements are essential for many advanced technologies, including wind turbine generators, electric vehicle motors, and other clean energy applications crucial for the global energy transition.”

Growing Demand for Rare Earth Elements

The shift to clean energy is making rare earth elements more in demand than ever. These minerals are key for many clean energy technologies. Rare earths are divided into two sub-categories: light rare earths and heavy rare earths.7

REE demand is set to jump 400-600% in the coming decades. This is to support the growth of wind turbines, electric vehicles, and clean energy solutions7. A single electric car needs six times more minerals than a traditional car. An onshore wind plant requires nine times more minerals than a gas plant8. This surge in demand is ahead of supply, raising concerns about these critical minerals8.

Neodymium, praseodymium, dysprosium, and terbium are crucial for wind turbines and electric motors7. Lithium, cobalt, and nickel are also in high demand for lithium-ion batteries in electric vehicles and energy storage8.

Experts say the supply of these minerals might not meet demand by 2030, even with global climate goals8. This imbalance raises worries about China’s control over the rare earth market. China produces over 80% of the world’s REEs9.

“The demand for minerals from low-carbon power generation is expected to triple by 2040, with wind and solar power being the leading sectors contributing to this increase.”8

The push for a clean energy economy makes a steady and sustainable rare earth supply crucial9.

Current Rare Earth Element Supply and China’s Dominance

China is a big player in the global rare earth element (REE) market, controlling a big part of the world’s supply10. It supplies over 80% of the world’s rare earth elements10. This makes countries want to grow their own and varied supply chains to lessen their dependence.

United States and Australia’s Production

Even though China leads in REE, other countries are boosting their production. The United States makes about 14% of the world’s rare earth elements10, and Australia makes around 6%10. They aim to increase their REE production to lessen their need for China and secure a steady supply of these important resources.

Dependence on Critical Minerals and Diversification Efforts

The world’s need for China for critical minerals like rare earth is a big worry11. China processes about 90% of REE globally11, giving it a lot of control over the supply chain11. So, countries are working to spread out their supply chains and cut their dependence on China.

The United States sees the need to grow its own rare earth production and processing10. The US Department of Energy says the country’s move to reduce carbon emissions depends on Chinese companies and the Chinese government10. Japan has also cut its rare earth imports from China from over 90% to 58% in ten years10. These moves to diversify and lessen dependence on China are key to a steady and safe supply of rare earth elements.

China’s big role in the rare earth market has been dropping in recent years10. Its share of global REE production fell from 92% in 2010 to 58% in 202010. Yet, China still has a big impact, buying stakes in mining companies in the US and Australia10. As demand for rare earth elements grows, diversifying supply chains and reducing reliance on China is vital for a sustainable and secure supply.

“The U.S. decarbonization goals are reliant on both Chinese firms and the Chinese government.”

Environmental Impacts of Rare Earth Mining

Extracting and processing rare earth elements can harm the environment. This includes toxic waste, pollution, and radioactive contamination12. China leads in rare earth production, making up 70% of the world’s supply. This has raised worries about mining’s effects on the environment12.

Toxic Waste and Pollution from Mining

Rare earth mining creates a lot of toxic and radioactive waste13. In China’s Baotou, mining has polluted soil and water, affecting local health12. In the U.S., cobalt mining in the Idaho Cobalt Belt has contaminated water, making it a Superfund site12.

Case Studies: China’s Rare Earth Capital and Idaho Cobalt Belt

In China’s Baotou, mining has grown fast, causing big environmental problems12. Over 1.5 million tons of radioactive waste has built up near homes and beaches, posing health risks12.

In the Idaho Cobalt Belt, mining has harmed the environment too12. The pollution has made the area a Superfund site, showing the need for better mining methods12.

Rare earth mining’s effects are worrying. They pollute soil and water, cause radioactive contamination, and harm ecosystems13. We need sustainable mining and recycling to lessen these problems13.

| Country | Rare Earth Production (2022) | Rare Earth Reserves |

|---|---|---|

| China | 70% (210,000 metric tons) | 44 million tons |

| United States | 14.3% | – |

| Australia | 6% | – |

| Vietnam | – | 22 million tons |

| Russia | – | 21 million tons |

| Brazil | – | 21 million tons |

“Rare earth mining has significant environmental impacts, prompting the need for recycling initiatives.”13

The mining of rare earth elements is harming the environment. It releases toxic chemicals, radioactive waste, and pollutes the air13. As we move to clean energy, recycling and sustainable mining are key13.

Sustainable Approaches to Rare Earth Supply

As the demand for rare earth elements (REEs) grows, researchers are looking for sustainable ways to get and process these minerals. They are focusing on biomining and electrokinetic extraction as promising methods.

Biomining: Using Microbes for Extraction

Biomining uses special microbes to get REEs from ores or recycled e-waste14. This green method aims to lessen the harm of traditional mining, which often uses harsh chemicals and creates toxic waste. Scientists are working on biomining to make rare earth mining greener and cheaper14.

Electrokinetic Methods for Improved Efficiency

Electrokinetic extraction is another new way. It uses electric fields to make rare earth separation and recovery better. This method could use fewer chemicals and less water than old methods14. Researchers aim to get REEs in a way that’s better for the planet.

These new ways to get rare earth are key as demand is set to jump by up to 7 times by 204014. With the USGS saying we made 240,000 tonnes of REEs in 202014, we need to find eco-friendly ways to get and process these minerals. This is vital for clean energy tech, like electric cars and wind turbines.

“The success of the REEsilience project is expected to have significant implications for Europe’s energy landscape as it secures a reliable supply of rare earth elements for the continent’s energy transition.”15

Projects like the REEsilience in Europe are pushing for sustainable rare earth supply chains. They focus on new extraction methods, recycling, and finding other materials15. These efforts aim to tackle environmental issues and supply chain problems for a greener and more secure rare earth future.

Agromining: Cultivating Hyperaccumulative Plants

Agromining, also known as phytomining, is a new way to get valuable resources and clean polluted land. It uses “hyperaccumulative” plants that can pull metals and minerals from the soil16. These plants include rare earth elements (REEs).

After picking these plants, they are burned. This leaves ash that has more of the target elements than traditional mining ores. This method is better for the environment than old ways of mining rare earths16.

Studies show agromining can get REEs from plants. For example, vineyards can get up to 900 milligrams of REEs per hectare without taking everything16. Some plants, like the fern Dicranopteris linearis, have more REEs in them than low-grade ores17.

Getting REEs from the ash of these plants works well, with up to 75% recovery17. Researchers suggest a three-step process to get the most REEs from the ash. They are testing different conditions to make it better17.

Other plants, like Salix (willow), are also good for getting REEs and cleaning polluted places18. These plants can hold a lot of REEs in their roots. This stops these metals from getting into the environment18.

Agromining could be a big deal for getting rare earth elements in the future. It’s a green way to meet the growing need for these materials in clean energy and tech161718.

“Agromining, or phytomining, is a technique that cultivates ‘hyperaccumulative’ plants capable of absorbing and storing metals and minerals, including rare earths, from contaminated soils.”

| Hyperaccumulator Plant | REE Concentration | Extraction Efficiency |

|---|---|---|

| Dicranopteris linearis (Fern) | 2-3 mg/g in fronds | 75% REE recovery |

| Salix (Willow) species | Up to 8,404 μg/g DW in roots | 85-89% REE retention in ash |

| Vineyards | 900 mg/ha without harvesting whole plant | Not specified |

Recycling Rare Earths for the Energy Transition

The world is moving fast to fight climate change, and that means we need more rare earth elements (REEs). These minerals are key for clean energy tech like wind turbines, electric cars, and solar panels19. But mining them can harm the planet and create global risks. Recycling is now seen as a better way to get these minerals.

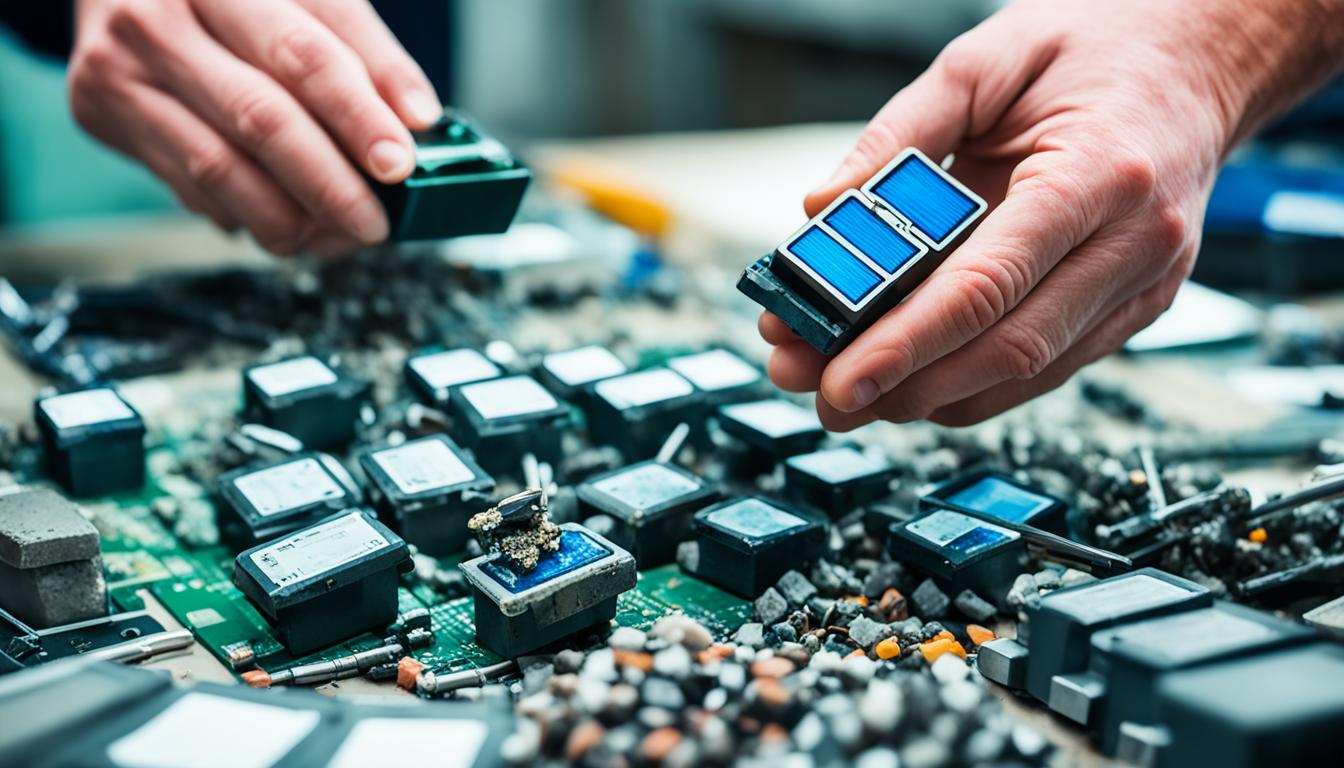

In Kingston, Canada, Cyclic Materials is at the forefront of rare earth recycling. They’re making new ways to get REEs from old electronics and waste19. This not only cuts down on mining harm but also starts a circular economy for these vital minerals.

Recycling rare earths is crucial for our energy shift20. We need to install more solar panels, wind turbines, and electric cars by 2040 to reach zero emissions19. Recycling can meet this demand without the mining problems.

| Mineral | Projected Demand Increase by 2040 |

|---|---|

| Copper | 40%21 |

| Rare Earth Elements | 40%21 |

| Nickel | 60-70%21 |

| Cobalt | 60-70%21 |

| Lithium | 90%21 |

Recycling rare earths does more than help with energy transition20. It’s key for recycling wind turbines, solar panels, and batteries, which have grown 50% since 201019. A circular economy approach can greatly lessen the clean energy’s environmental impact.

Though recycling rare earths faces challenges, the benefits are big21. The IEA says recycled metals from spent batteries could meet 10% of demand by 204021. With more research and investment, recycling rare earths could be a big part of a sustainable energy future.

“Recycling can help reduce the environmental impact and dependence on mining, while also creating a circular economy for critical clean energy minerals.”

Challenges in Recycling Rare Earths

Recycling rare earth elements (REEs) is a key way to meet the growing demand. But, it faces big technical and economic hurdles. Rare earth recycling challenges come from the complex waste streams and the high costs of separating and extracting these minerals.

Technical Barriers

Getting REEs out of waste, like from electronics and batteries, is hard. They’re often mixed with other metals, making them tough to remove22. Old recycling methods use harsh chemicals and a lot of energy, which is bad for the planet22.

New methods, like using bacteria or the copper salt process, might help. But, they’re still being tested22. The copper salt method can get 90-98% of REEs back, but making it big and keeping quality up is hard22.

Economic Viability

Recycling REEs is pricey, often more so than mining them fresh. This makes it hard to compete financially22. Right now, only about 1% of REEs from old products get recycled22.

But, some companies are finding ways to make it work22. For example, “TdVib” in Iowa is building a plant to make rare earth oxides with the copper salt method. They’re focusing on recycling from old hard disk drives22. In Texas, Noveon Magnetics mills magnets into powder for making recycled magnets, skipping the expensive steps of extraction and separation22.

Even with these steps forward, technical barriers and economic viability are big hurdles. Scaling up rare earth recycling to meet demand is still a challenge2223.

“Recycling rare earths from tossed-out items remains challenging due to blending with other metals, making removal difficult.”22

Role of Policies and Research in Promoting Recycling

The world is moving towards a sustainable energy future, and the need for rare earth elements (REEs) is growing fast24. Electric vehicles and renewable energy technologies like wind and solar use more minerals than old energy sources. This means we need a steady and green supply of REEs24. To meet this need, policymakers and researchers must work together to boost rare earth recycling and make supply chains strong.

Government support is key to increasing rare earth recycling. By funding research, offering tax breaks for recycling, and setting rules for circularity, we can overcome the hurdles to recycling rare earths25. This support can encourage companies to invest and innovate, speeding up the shift to a sustainable rare earth supply.

Research and innovation are vital for improving rare earth recycling. Scientists and engineers are finding new ways, like biomining and electrokinetic methods, to make recycling more efficient and cheaper25. These new technologies can lessen our need for primary mining and reduce the environmental harm from rare earth supply chains.

Working towards sustainable sourcing and a circular economy for rare earths also matters a lot. With eco-friendly design, recycling goals, and producer responsibility, we can tackle waste and resource issues in the clean energy sector25. By focusing on reuse and recycling, the industry can aim for a sustainable and strong rare earth supply.

As we move to a low-carbon future, the need for rare earth recycling will keep growing24. With the right policies, research, and circular economy strategies, we can make the most of rare earth recycling. This will ensure a steady supply of these key materials for the energy transition25.

Case Study: Kingston, Canada’s Rare Earth Recycling Hub

Kingston, Ontario, is becoming a key place for recycling rare earth in Canada26. It’s close to big car and clean tech centers and has a lot of skilled people from nearby universities. This makes Kingston a leader in making sustainable supply chains for important minerals for clean energy26.

Cyclic Materials, a new company started in 2021, is at the center of this effort26. They’re working on new ways to extract and process rare earth. In 2024, they opened a big plant in Kingston, which is a big step for the city in rare earth recycling26. They plan to open more plants in North America, Europe, and Asia, making Kingston a key part of the circular economy for these minerals26.

Big companies like Solvay are also helping Kingston grow in rare earth recycling26. Solvay is a global company with lots of employees and sales. They work with others to make sustainable solutions for rare earth, which are key for things like electric cars and wind turbines26.

The Canadian government is also putting money into Kingston’s clean tech scene27. In 2023, they gave $4.2 million to a project about rare earth extraction and separation in Kingston. This project will help make a new way to separate rare earth, which will help North America not rely so much on China for these minerals27.

The demand for rare earth is expected to go up a lot by 203026. Kingston is getting ready to be a big center for making sustainable solutions for these important resources. With its strengths and partnerships, Kingston is set to be crucial in moving to a greener, more independent clean tech future.

Conclusion

The need for rare earth elements (REEs) is growing fast to support clean energy. Recycling is becoming a key solution, not just mining28. The use of oil in the world has dropped from 49.6% to 33.1%, but we’re using more of it overall29. Solar and wind energy are getting bigger, which means we need more REEs.

Recycling REEs from waste can help the environment, lessen our dependence on China, and get us the materials for clean energy14. We expect to need up to 7 times more REEs by 2040. Recycling will be crucial to meet this demand. But, we face big challenges that need more research and policy support.

It’s vital to solve these issues and make sure we have a steady supply of REEs for clean energy28. A model by IFP Energies Nouvelles shows copper might be the biggest challenge as we move to cleaner energy. By 2050, almost 90% of copper might be used up. Electric vehicles need more minerals than traditional cars, and by 2050, they’ll make up 31.0 percent of all cars. We must secure a steady supply of REEs and other minerals for clean energy to succeed and meet climate goals.

FAQ

What are rare earth elements?

Why are rare earth elements important for the energy transition?

Where are rare earth elements currently produced?

What are the environmental concerns with rare earth mining?

What are some more sustainable approaches to rare earth supply?

What are the challenges in recycling rare earth elements?

How can policies and research support rare earth recycling?

What is the role of Kingston, Canada in rare earth recycling?

Source Links

- The Energy Transition Will Need More Rare Earth Elements. Can We Secure Them Sustainably?

- The Canadian city betting on recycling rare earths for the energy transition

- The Canadian City Betting on Recycling Rare Earths for the Energy Transition – News – Cyclic Materials

- Critical materials for the energy transition: Rare earth elements

- Critical minerals for the energy transition: rare earth metals

- Rare earths: vital elements of the energy transition

- The role and challenges of rare earths in the energy transition

- Executive summary – The Role of Critical Minerals in Clean Energy Transitions – Analysis – IEA

- Rare Earth Elements: A Resource Constraint of the Energy Transition

- China’s Grip On Rare Earth Elements Loosens

- Mapping the Impact and Conflicts of Rare-Earth Elements – Institute for Policy Studies

- Rare-earth mining is dirty but key to a climate-friendlier future

- Recycling rare earths: Perspectives and recent advances – MRS Bulletin

- REEsilience: Building a sustainable rare earth supply chain for Europe’s energy transition

- Accumulation of rare earth elements in common vine leaves is achieved through extraction from soil and transport in the xylem sap – Communications Earth & Environment

- A new method for recovering rare earth elements from the hyperaccumulating fern Dicranopteris linearis from China

- Phytoextraction and recovery of rare earth elements using willow (Salix spp.)

- The state of play – The Role of Critical Minerals in Clean Energy Transitions – Analysis – IEA

- Materials Shortage Will Not Stop The Energy Transition, If We Plan Ahead

- Recycling Critical Minerals for Circular Clean Energy Solutions

- How science could make recycling rare earth elements easier

- Rare earth metal recycling, role of circular economy in energy transition

- Executive summary – The Role of Critical Minerals in Clean Energy Transitions – Analysis – IEA

- Emerging waste streams: Opportunities and challenges of the clean-energy transition from a circular economy perspective

- Solvay and Cyclic Materials sign supply agreement for recycled mixed rare earth oxide

- Ucore Welcomes Canadian Government Officials to its Kingston Ontario CDF for an NRCan Funding Announcement

- IFPEN | Metals in the energy transition

- A Western Hemisphere Minerals Strategy for the Energy Transition